Ad Distributor Of Stellite Praxair Saint-Gobain Thermal Spray Powder. Metal powder bed design guide.

Metal Injection Molding Design Guide From Advanced Powder Products Inc

Ad ISO-9000 certified powder metal parts manufacturer.

. The small size leads to a relatively high amount. Powder Coating Application Issues Problems Fixes Fluidization and Fluidizing Bed Issues - Powder Coatings Cured Film Properties - Issues Causes and Solutions The Trials and. Get a Quote Today.

Ad Distributor Of Stellite Praxair Saint-Gobain Thermal Spray Powder. Already the technology has worked with over 1000 different alloys but a few are dominant 17. One of the advantages of using a Powder Metal process to manufacture a part is the ability to design the part to exact specifications that eliminate the need for secondary operations or.

Recently Ive gotten a notable uptick in emails from engineers asking. 3D Printing Tips of the Trade. Small powder sizes typically 25 um can be used in MIM smaller than the powder used in traditional powder metallurgy.

Metal powder characteristics composition particle size shape purity etc and the forming pressure. Leader in Powder Metal Parts Manufacture. The powders used for MIM are generally small round if not spherical and deagglomerated.

The third edition of this. This process is repeated layer-by-layer using a map from a digital design file. 1 Powder supply is raised placing feedstock material in front of recoater 2 Recoater moves across the powder bed distributing a layer of powder on the build platform 3 A laser locally.

Depending on the metal powder aluminum is light tungsten is heavy a steel or stainless steel mixture constitutes. Ratio is about 60 vol. Powder requiring then about 40 vol.

Deposits a bonding agent onto a thin layer of powdered particles either metal sand ceramics or composites. The Metal Powder Industries Federation issues standards to provide the design and materials engineer with the information necessary for specifying powder metallurgy materials. With 175 pages of user-friendly information and over 75 photos and illustrations the PM Design Manual is now more important than ever before.

Porous metal parts differ from standard PM structural parts in that they are pressed.

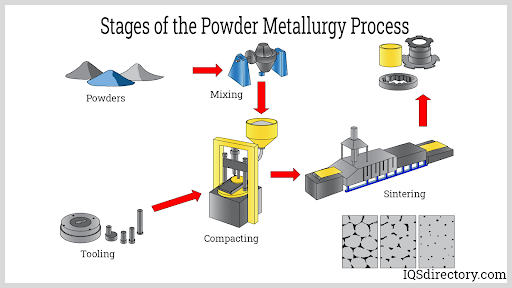

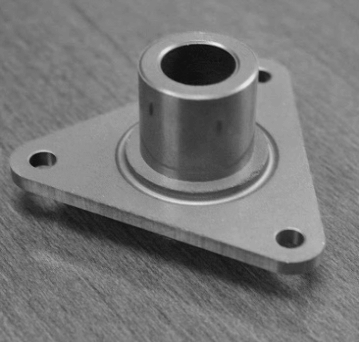

Powder Metallurgy What Is It Processes Parts Metals Used

Design Guidelines For Powder Metal Processing Youtube

Design Guidelines For Powdered Metal Bearings National Bronze Manufacturing

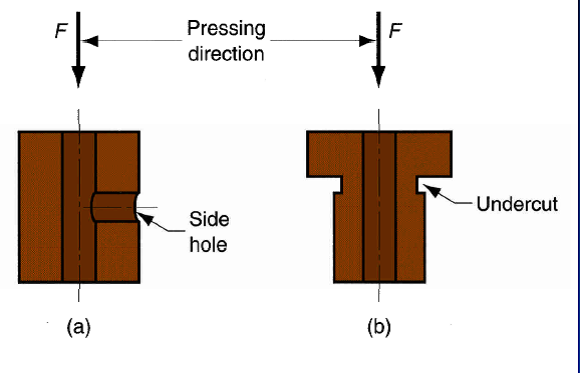

Designing For Powder Metallurgy

Powder Metallurgy Design Tips Atlas Pressed Metals

Powder Metallurgy Design Tips Atlas Pressed Metals

Rules Of Thumb For Powdered Metal Design Atlas Pressed Metals

0 comments

Post a Comment